Overhead & Headliner Systems

From headliners to grip handles and map lamps, Kasai Headliner Manufactures a complete overhead interior system for a wide range of customers. Our company provides a full design and development of complete…

Kasai is a full-service tier 1 automotive interior and exterior trim supplier providing parts for vehicles in all global markets. Kasai provides a one-stop solution for customer’s needs and is a leader in the market on innovation, with multiple award-winning patents and technologies emphasizing sustainable production. From luxury cars to commercial-grade trucks and buses, Kasai is committed to meeting and exceeding the customer’s needs.

From headliners to grip handles and map lamps, Kasai Headliner Manufactures a complete overhead interior system for a wide range of customers. Our company provides a full design and development of complete…

From simple Precision Injection Molding to fully wrapped body and door trims, Kasai has the capability and the expertise to design, develop, and manufacture all types of trim products. Learn about our…

Kasai provides full luggage systems from Luggage Boards, Tonneau Covers, Luggage Storage, and Luggage Side Trims. Cargo areas feature a full trim area with built-in features such as cup holders, cargo space,…

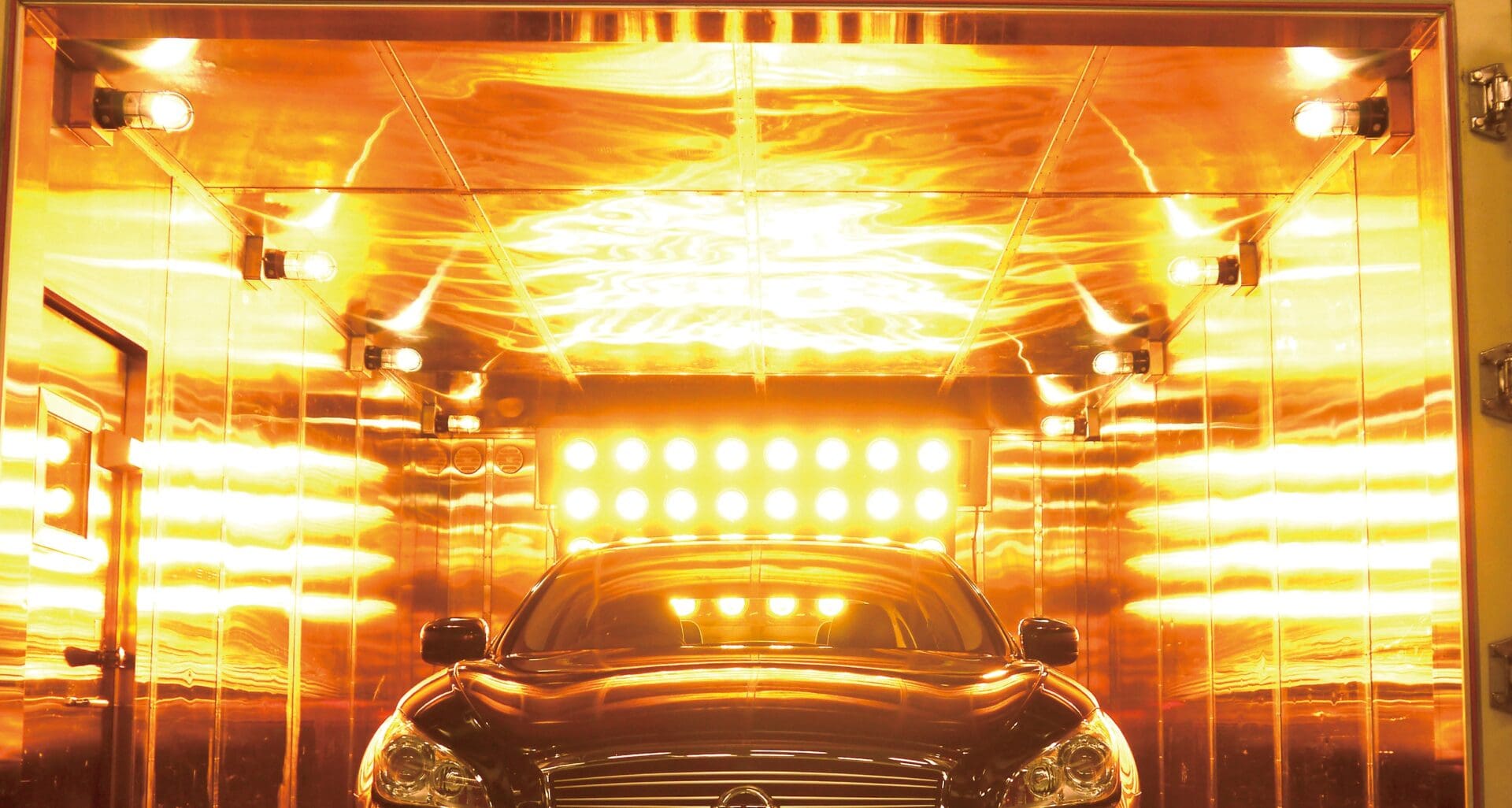

Kasai research and development is at the forefront of developing technologies for improving vehicle performance, and provide technologies that ensure good stewardship of the environment. From our KHP molding technology, which utilizes recycled material, to our award winning heat shielding headliner technology, Kasai strives to bring innovation to the market that provides value to the customer and superior performance improvement for the vehicles in the markets they serve.

Heat Shield Headliner (HSHL) technologies were developed by Kasai to improve cabin comfort and fuel economy in both traditional internal combustion and electric vehicles. This shielding technology is capable of reducing interior cabin temperatures by 10.2 degrees Celsius. The shielding layer is available as integrated layer in headliners and is ideal for improved fuel economy and lightweighting

Since 2015, Kasai North America has been operating a full testing facility in Manchester, Tennessee. The lab is capable of running validation tests for environmental, safety, material, and chemical analysis. Most customer required tests can be conducted in-house by our testing center at a lower cost than independent testing labs.